I’ve been around a lot of years, and I can’t remember a time when recruiters, recruiting managers, hiring managers, HR executives, and company leaders didn’t complain about the lack of good candidates. When the Internet and job boards came along, we were promised the solution was at hand.

I’ve been around a lot of years, and I can’t remember a time when recruiters, recruiting managers, hiring managers, HR executives, and company leaders didn’t complain about the lack of good candidates. When the Internet and job boards came along, we were promised the solution was at hand.

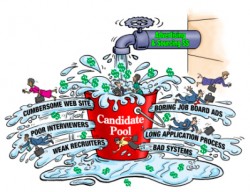

But more than a dozen years later, the problems in finding talent have gotten worse, not better. I’m going to suggest that sourcing is not the problem, and that much of the solution has nothing to do with seeing more candidates.

I equate hiring top performers as a business process similar to manufacturing. My early industry background was in high-volume consumer electronics and automotive components, so this comparison is easy for me to make. In a factory when you have excessive scrap you need to either buy extra raw materials or reduce the scrap rate. This is not rocket science, but somehow the obvious seems to be overlooked when it comes to hiring.

(Note: in this article substitute prospects or candidates whenever you read the term “raw materials.”)

When sourcing is viewed as a factory, with prospects coming in at the receiving dock and accepted offers coming out of shipping, you quickly notice two problems. One, the raw material is incorrectly specified or over-specified, and two, the process used to convert the raw material into accepted offers is based more on emotion than science.

In a factory, excessive scrap is usually due to a combination of bad material specs, inconsistent processes, and weak controls. In hiring, these are equivalent to weak job descriptions, managers who evaluate the wrong things incorrectly, and the lack of metrics.

This requires recruiters to find more raw materials than necessary. This becomes problematic when recruiters over-rely on boring advertising and unsophisticated selling techniques to attract a diminishing supply of coveted raw materials.

To make matters worse, when finalists are selected and offers are about to be made, recruiters and managers stumble through some clumsy closing process either paying too much or losing the candidate to a more professional and astute buyer. When viewed in this light, the idea of buying more raw materials or looking for more candidates makes no sense until the rest of the processes are fixed.

Here are 20 common non-sourcing problems (if you have more than 10, fix your sourcing scrap rate before you look for more raw materials):

- Job descriptions are boring.

- Managers over-specify skills, experience, academics and industry background.

- Application process is too long and top candidates opt-out.

- Managers don’t spend enough time clarifying real job needs.

- Managers refuse to see good candidates, because they don’t have exactly the right background.

- Managers exclude good candidates due to incorrect assessments.

- Managers don’t respond quickly enough when resumes are sent to them.

- Good candidates are unimpressed with our interviewing process.

- Good candidates are unimpressed with the hiring manager.

- Good candidates want to know the comp before talking.

- Passive candidates want to know the details of the job before even talking.

- Recruiters over-rely on skills and experience to screen candidates.

- ATS system is cumbersome to use.

- Candidates increasingly are rejecting offers or accepting other offers or better offers.

- We can’t attract the best people with our comp packages.

- Recruiters can’t smoothly handle most candidate concerns.

- Relocation is a problem.

- We can’t move fast enough to decide & make offers.

- Managers aren’t responsive or involved enough.

- We never have enough time to do it right.

Avoid Preventable Issues

How many unnecessary extra candidates do you need to find to overcome all of the good candidates who were lost for the above preventable reasons? Many of these non-sourcing problems are attributed to weak planning, lack of training, dumb policies, bad processes, and inadequate technology.

When viewed from this perspective, it’s apparent that there is a lot of non-sourcing stuff that can be done to help reduce the need to see more candidates.

But this is still only half of the problem. If you have more than 10 of the following sourcing-related problems, improving your scrap rate will help, but not enough to solve the problem completely.

Sourcing-Related Problems

- The quality and quantity of candidates from job boards is declining.

- We use the same sourcing methods every year.

- Our advertising is boring and out-dated.

- Our job ads are just cut-and-paste versions of our boring job descriptions.

- Ads are hard to find by top people who are casually looking.

- Ads are found, but top candidates don’t apply.

- Our ads don’t describe a compelling value proposition.

- Our ads are filled with disqualifiers and little about what’s in it for the candidate.

- Our ads are written to exclude bad people not attract good people.

- Our career website is difficult to navigate and search for jobs.

- We don’t use web analytics to track response by ad.

- We have not search engine optimized our site or our ads.

- Our ads don’t always come up first on the job boards we use.

- Good candidates say they’re “not interested” early in the process.

- We don’t get enough high-quality referrals.

- Too many voice-mails are needed to get callbacks.

- We make too many cold calls to passive candidates.

- High-potential candidates with slightly different skills would not naturally apply to our ads.

- Our CRM system and resume database is difficult to use and not very effective.

- Our employees don’t proactively seek out great people to refer.

Too many companies try to solve their hiring problems with a new sourcing-idea-of-the-month program. This is like applying a Band-Aid when major surgery is required.

Instead, think big and fix your scrap rate problems first and then start posting compelling ads in exactly the same places. Before you know it, your talent factory will be humming along.